Glass Gluing System

Home » Capabilities Overview » Sealant System » Glass Gluing System

Our Solutions for General Assembly

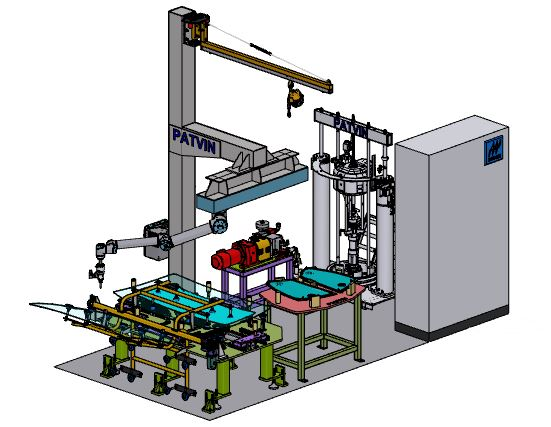

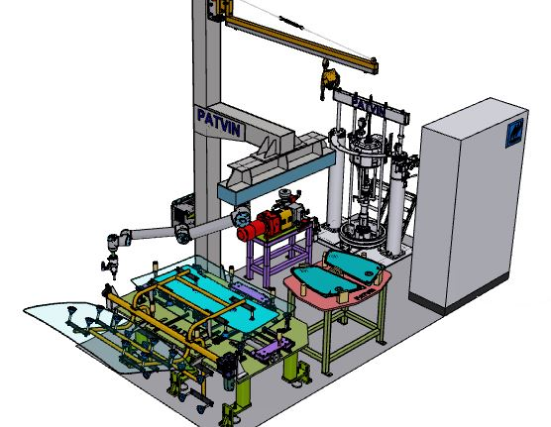

Glass gluing system

Glass bonding is another important adhesive application in the automotive industry. Polyurethane is commonly called urethane. This is an adhesive specially developed for the sealing and bonding of windshields, side windows, quarter windows and rear windows in the automotive industry.

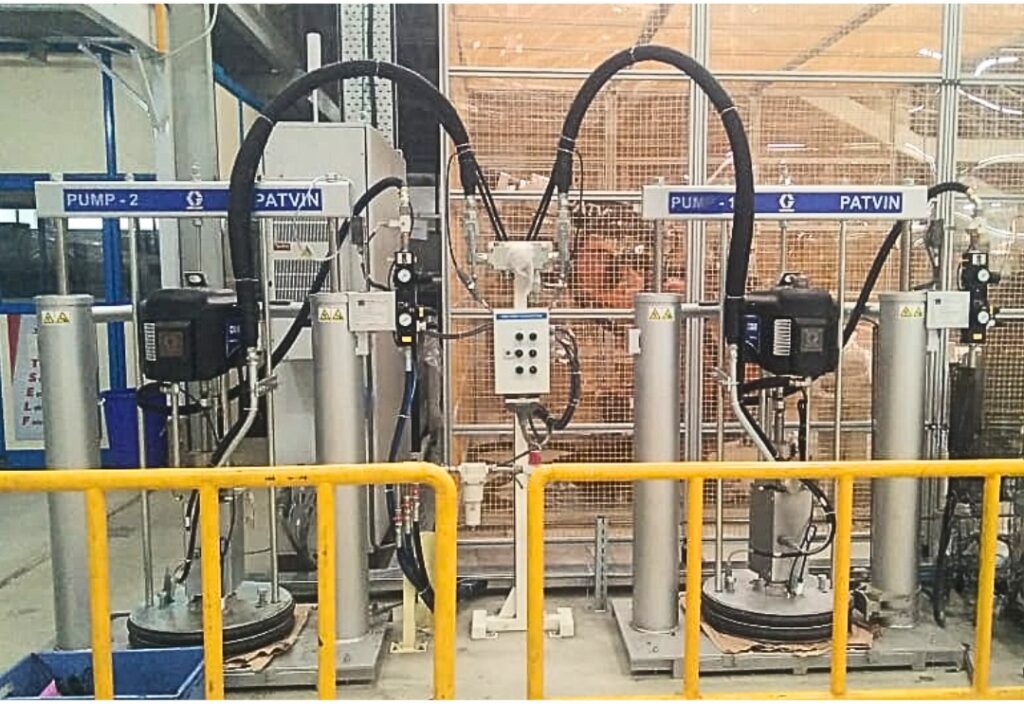

Urethane supply system

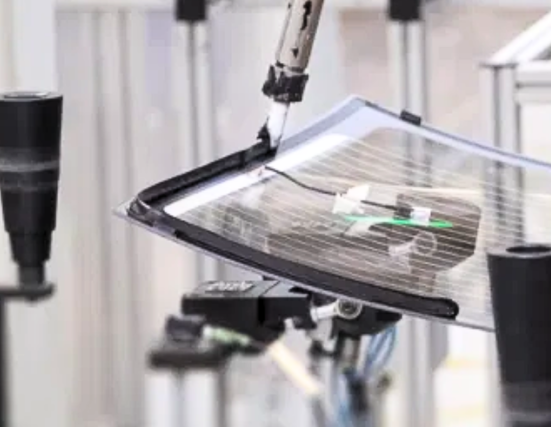

Dispense Head

- It comprises of dispense gun with Rotating nozzle head.

- It has been provided for integrating the Robot 6th Axis for the rotation of gluing nozzle for ease of robot programming.

Heated Hose

- Insulated Stainless Steel Braided PTFE Warm Melt/Hot Melt Heated Hose are designed to give accurate and uniform temperature conditioning for your Sealant and Adhesive applications.

- Use these hoses to keep your material at the ideal temperature for the best possible dispense quality.

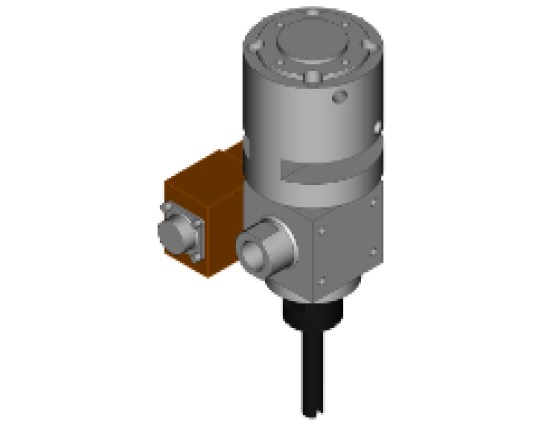

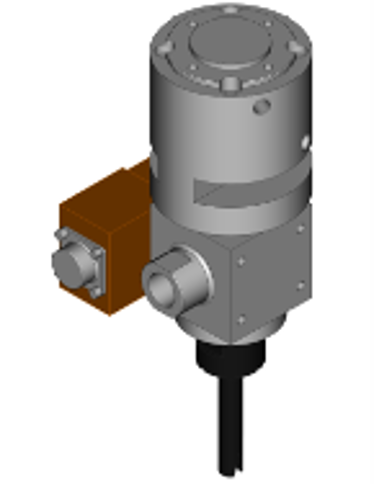

Gear metering Pump

Our Gear Metering System is equipped with a PLC and Servo drive, ensuring a continuous flow of sealant without any interruptions. This system provides accurate metering and complete control, producing a smooth and consistent bead every time. Additionally, the pressure sensors installed at the inlet and outlet monitor pressure levels closely while being interlocked to prevent any dry running of the pump. Click here to learn more.