Thermal Management

Home » Capabilities Overview » EV BATTERY » Thermal Management

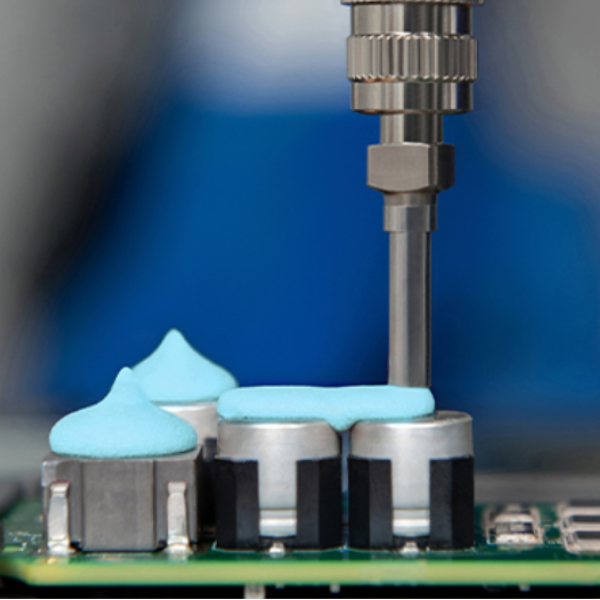

Thermal interface materials used in gap filling applications are critical to overall battery performance and safety. When dispensed correctly, the gap fillers dissipate heat away from the battery, improving battery speed, longevity and decreasing the likelihood of thermal events.

However, pumping and dispensing thermal interface material (TIM) brings many challenges to electric vehicle (EV) battery assembly lines. Highly abrasive and low viscosity in nature, the gap filler can quickly wear out equipment. TIM also needs unique attention to pressurization to ensure optimal heat transfer.

To withstand this tough material, manufacturers should consider robust equipment that allows for high flow, precise metering and dispense.

Advantages:

- Critical to overall battery performance and safety

- Dissipate heat away from the battery

- Improves battery speed & longevity

- Decreases the likelihood of any thermal events

Patvin Engineering Solutions: