Ransburg

Home » Capabilities Overview » Paint Application System » 2K/DOSING » Ransburg

Ransburg - Intelliflow RM2 Pump

IntelliFlow – The next generation of intuitive, accurate, connected proportioning solutions

The IntelliFlow RM2, an entry-level electronic plural component proportioner, is designed to minimize waste and maximize consistency for a wide range of hand spray applications. The unit can manage up to seven colors and two hardeners, a major milestone in hand spray applications. The versatile unit is available for low pressure, medium pressure or acid catalysts configurations.

- Up to 7 colors; mix ratios up to 100:1

- Easy operation and seamless installation

- Generates a proven ROI for your business

- Touchup or full production

- IntelliFlow products deliver advanced automation and ease of use to drive efficiency, uptime, and process optimization. The unit has large, color touchscreens with automated processes reduce training time and operator error. Cloud-based connectivity allows remote monitoring and real-time diagnostics.

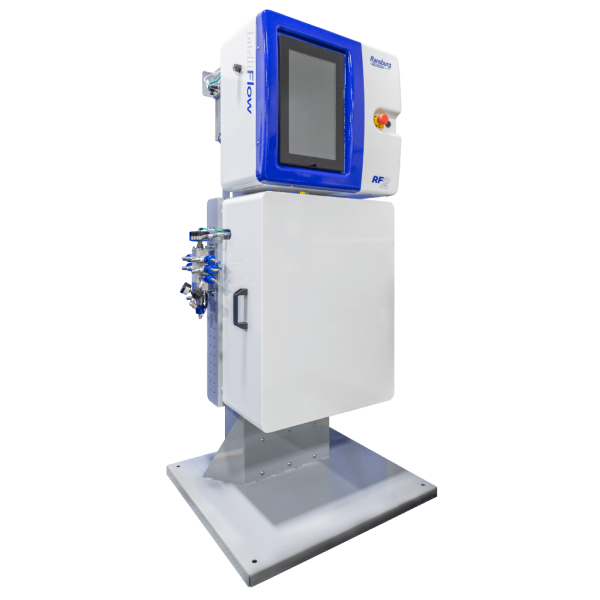

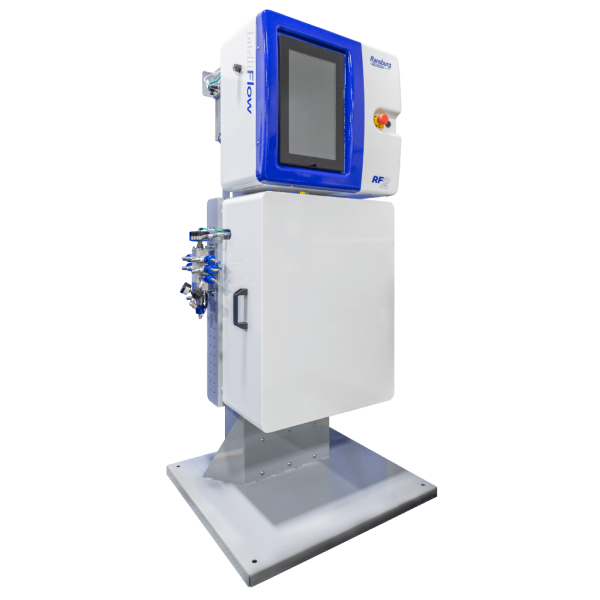

Ransburg Intelliflow RF2

The IntelliFlow RF2 is available in two models; manual mode for hand spray applications or automatic for robot or hand spray applications. The unit is designed to maximize process savings for almost any applicator system, including static, reciprocator, flatline, and robot applications. Seamless integration capabilities allow the RF2 to be installed in almost any new or existing process and immediately begin delivering cost savings.

With up to 30 colors, 6 catalysts, 3K, and multi-circuit capabilities, the RF2 can be tailored to your specific needs, and then grow alongside your business using its modular architecture.

RCS 2 Metering & Mixing

RCS 2 is the latest generation 2K and 3K mixing and metering Ratio Control System. If you’re looking for applications with short trigger times, fast response, low latency, low flow, etc. this system can be the perfect choice.

It is known for its efficiency and reliability. This Radio Control System features magnetically coupled metering pumps which prevent shaft seal leaks. This system can be used with solvent-borne or waterborne materials.

RCS 2 can be easily integrated with automatic and manual systems with one or multiple applicators. They can be used with rotary atomizers, bells, disks, and either electrostatic or non-electrostatic spray guns.

The software offers user-friendly programmable alarm tolerances, a programmable pot-life timer, and multiple flow rates and ratios. The best part about this RCS 2 is it can accommodate color-to-color changes with ease and without any color carryover.

FEATURES

- A common computer based graphical user interface

- Built-in system diagnostics

- Intelligent time and date stamped fault messages

- Configurable fault conditions and tolerance

- 199 parameter sets per gun

- Comprehensive context-sensitive help screens

- Pot-life timer and pressure pot volume monitoring and alarming

- Forcible discrete and analog inputs and outputs

- Ability to update (flash) firmware on-site with a laptop

- Password protection of all operational parameters

- Data acquisition style trending screens

- Proportional flow rates based on number of applicators being triggered

OPTIONAL FEATURES

- A programmable 10-color, 12-step color change sequencer

- In-booth intrinsically safe operator interface panel

- The ability to be retrofitted to existing RCS fluid panels

- EtherNet/IP communication

Ransburg - Intelliflow RM2 Pump

IntelliFlow – The next generation of intuitive, accurate, connected proportioning solutions

- Up to 7 colors; mix ratios up to 100:1

- Easy operation and seamless installation

- Generates a proven ROI for your business

Ransburg Intelliflow RF2

The IntelliFlow RF2 is available in two models; manual mode for hand spray applications or automatic for robot or hand spray applications. The unit is designed to maximize process savings for almost any applicator system, including static, reciprocator, flatline, and robot applications.

RCS 2 Metering & Mixing

RCS 2 is the latest generation 2K and 3K mixing and metering Ratio Control System.

- A common computer based graphical user interface

- Built-in system diagnostics

- Intelligent time and date stamped fault messages